Engineering / Product Development

Requirements

Before any product design is started, we work to understand our customers’ requirements. We ask questions, and then we listen. We gain an understanding of the application. We will visit sites where the product will eventually be used. As we learn, we document the product requirements.

When this process is complete, a formal Specification exists for the product to be developed. This Specification identifies all product requirements that must be met, such as operating temperature, functionality, linearity, governmental regulations, etc.

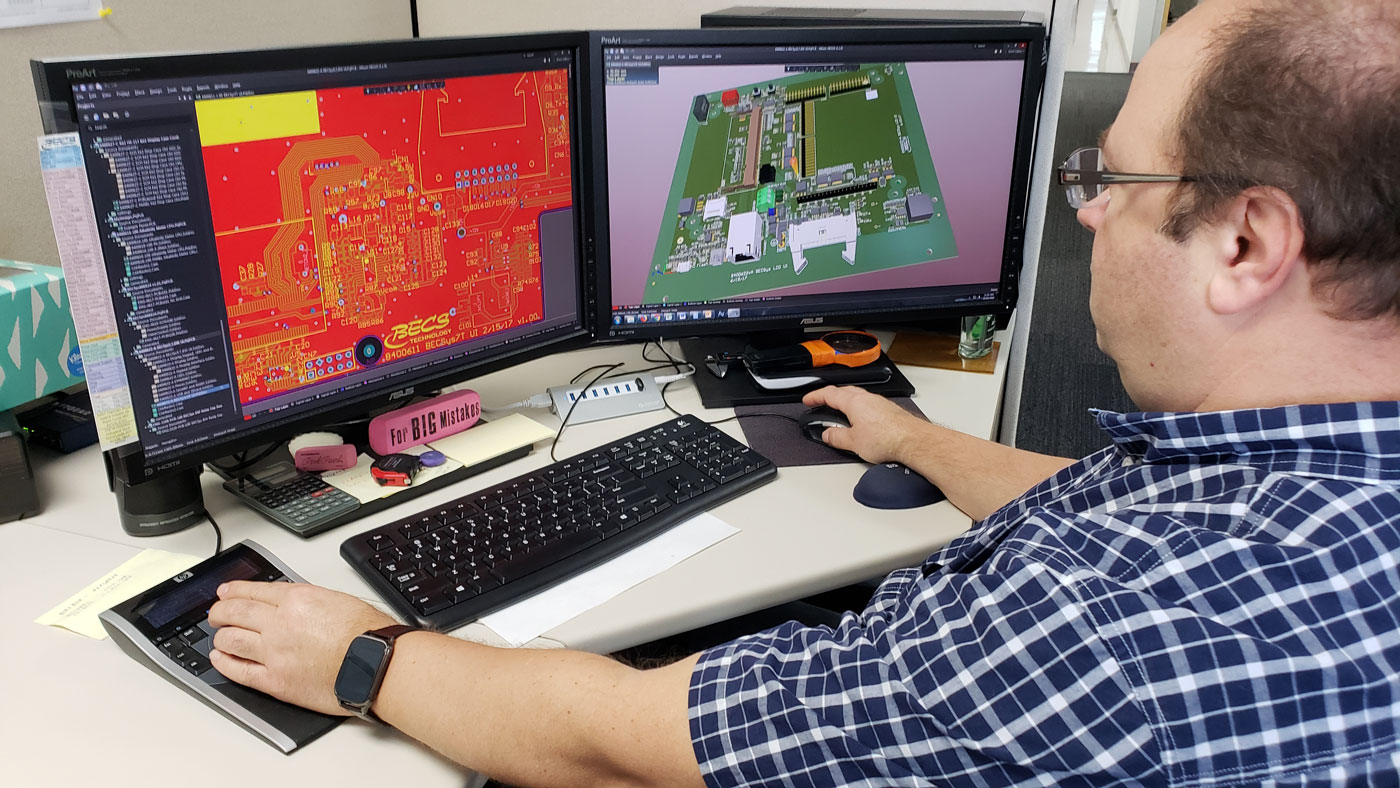

Design

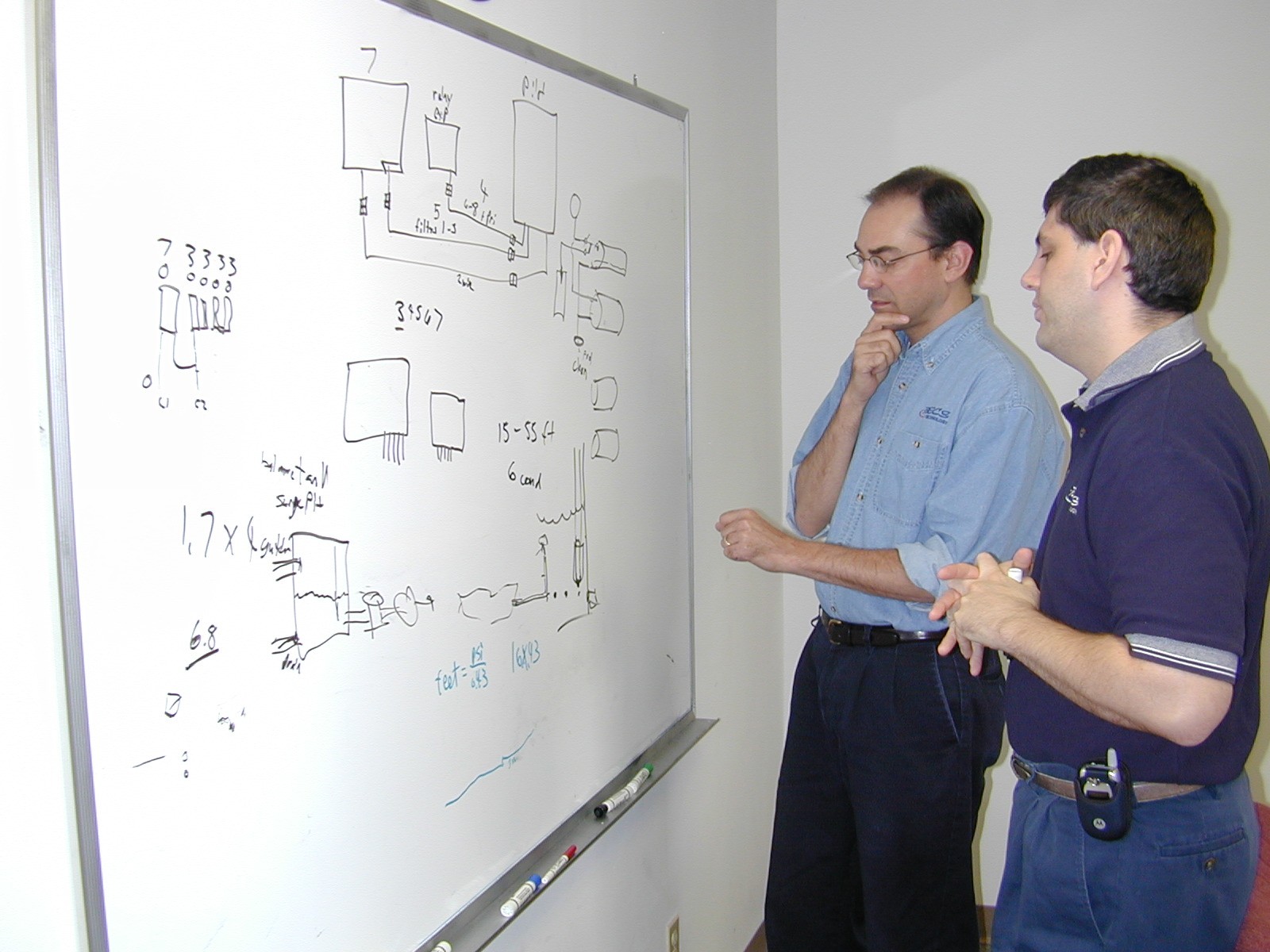

Design Analysis & Review

As part of the design process, a comprehensive series of analyses and reviews are conducted to scrutinize the system and assure its reliability. Every design analysis includes:

- Failure Modes and Effects Analysis (FMEA) details how the system will perform (the “Effects”) in the event of an individual component failure.

- Component Stress Analysis assures that each component in the system is being used within the tolerances of that component. All components in a product designed at BECS are required to operate within 80% of their specified operating range.

- Other analyses as required by the design

Qualification

Once a design has been completed, analyzed and reviewed, a limited number of prototypes will be constructed. These prototypes will be subjected to a full functional test, to verify that the system will operate as specified. Our in-house Aquatics Lab provides a way to functionally test BECSys products in a simulated, controlled environment.

After successful functional test, prototypes will be taken to our in-house Qualification Lab where a rigorous qualification test will be executed. This Qualification Test will subject the unit to abnormally harsh conditions, to confirm system performance in even the most severe environments. Qualification testing includes things like extreme temperature and humidity cycling, electrical fast transient, static discharge and inductive coupling tests.